While the human eye can detect electromagnetic radiation in the visible light spectrum, all other forms of electromagnetic radiation, such as infrared, are invisible.

Discovered in 1800 by astronomer Frederick William Herschel, infrared radiation lies between the visible and microwave portions of the electromagnetic spectrum. The primary source of infrared radiation is heat, or in the case of water and wastewater applications, abnormal pump and electrical device conditions.

To identify these problems, Leong Au, CBC Service Technician, says water and wastewater operators rely on thermal imaging cameras to record radiation intensity. He adds that by highlighting potential problems before they arise, radiation detection serves as predicative maintenance.

“Thermal imaging has evolved into one of the most valuable diagnostic tools for predictive maintenance in the water and wastewater sectors, facilitating increased reliability and critical asset uptimes,” Leong says.

“By detecting anomalies often invisible to the naked eye, thermography allows corrective action to be taken before costly system failures occur.”

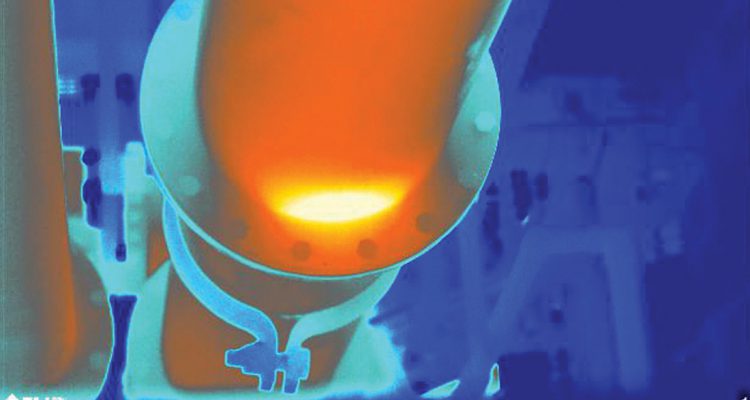

Infrared thermography is the art of transforming an infrared image into a radiometric one, which allows temperature values to be read from the picture. “Every pixel in the radiometric image is in fact a temperature measurement. In order to read this, complex algorithms are incorporated into thermal imaging cameras, which makes them a crucial tool for electrical and mechanical water applications,” he says.

To facilitate predictive maintenance for their clients, Leong says CBC, in partnership with leading thermal imaging camera design and manufacturing company FLIR, offer a full range of thermology cameras suited to the water industry.

He adds that due to CBC’s fully accessible range of stock, cameras can be purchased on demand and delivered at lighting quick speeds.

FLIR thermal cameras are able to identify unstable connections between main electrical cables, highlighting which phases are operating at higher temperatures.

“Infrared technology provides thermal images of temperature differentials within the detection field. It is then reliant on a human understanding of the image to determine the presence of faults, which is why it’s important to work with qualified technicians,” he says.

Leong adds that it is common practice for insurance companies to require 6-12 months’ worth of external audits on all electrical panels in water applications. As such, operators require consistent monitoring.

“When dealing with mechanical systems at water treatment plants, infrared images can detect problems such as bearings running at high temperatures. This is often the fault of misalignment or a lack of lubrication, both relatively easy fixes that can prevent further corrosion or even explosion,” Leong says.

According to Steven Blott, FLIR Systems Country Manager Instruments, FLIR’s partnership with CBC began in 2010.

“When the price of thermal cameras went down, interest went up, which meant we needed to work with out-of-house distributors to match demand,” Steven explains.

“FLIR engaged CBC because we knew they had the customer focused mentality and technical abilities required to positively represent and distribute our products.”

When an operator doesn’t take a thermal photograph correctly, for example not focusing the lens or using the correct temperature scale, the resulting picture will be inaccurate.

“Whoever said a picture paints a thousand words was absolutely correct. The image has to tell a thermal story of what’s going on with internal machinery and water pumps. If not, the problem is going to persist, costing clients time and money,” Steven says.

Following initial engagement, FLIR worked with CBC to train technicians in level one thermology. From there, in addition to being a product they supply, FLIR cameras became a core component of CBC’s maintenance kit.

According to Steven, working with an organisation like CBC is highly valuable because while operators can buy cameras outright online, there is no back-up support when issues arise.

“Without local support, operators are unable to simply pick up the phone when they have issues,” he says.

“Additionally, if they have to ship their camera overseas for diagnostics, they lose the ability to apply predictive maintenance for an extended period of time, which can have dire consequences when dealing with water and electricity.”

Alternatively, CBC and FLIR offer a complete package, with after-sales support, servicing and ongoing diagnostic assistance.

“CBC is focused on bringing qualified, experienced and technically savvy personnel together within our engineering services team and across the organisation on a broader scale,” Leong says.