From the design and drafting, to the manufacturing and commissioning, CBC Australia provides customers in the wastewater market segment with an end-to-end solutions-driven service.

According to Engineering Manager Anthony O’Keefe, having the capability to identify component details and then supply unique spare parts, has set CBC apart from Original Equipment Manufacturers (OEMs) and their competitors in this sector.

“We’ve found that in the water and wastewater segment, we’re getting a lot of requests to deliver unique spare parts. We have the capabilities to come onto a customer site, identify exactly what components are being used and where they have come from. We’ve got the skills and know-how to identify the details as well as design and manufacture the parts. Furthermore, our engineering program extends to the installation and servicing of those components after we’ve supplied them.”

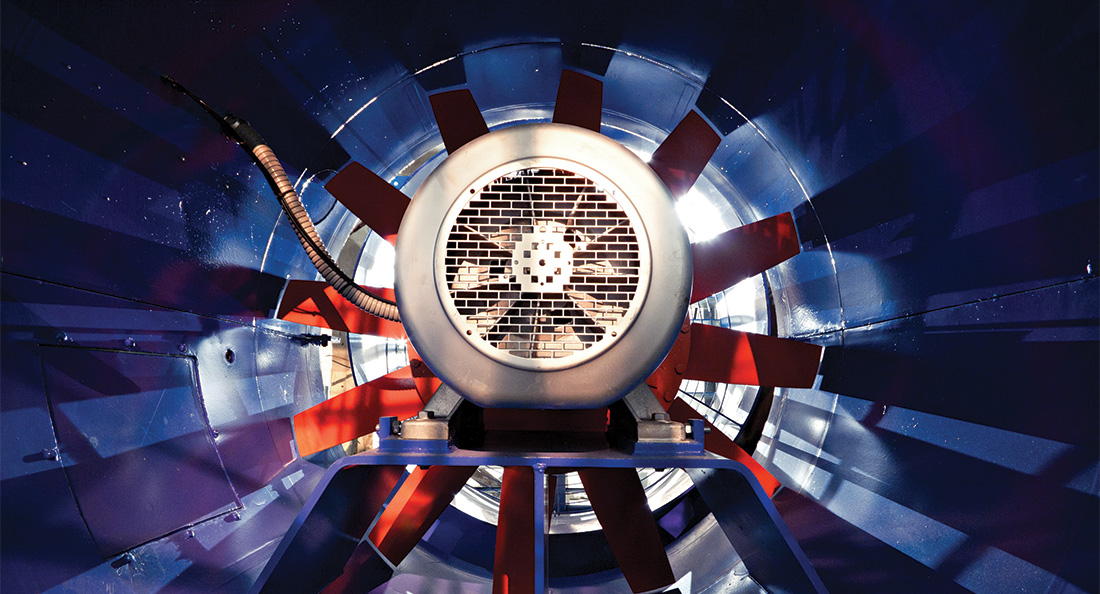

In fact, CBC Group Engineering have developed a specialist two-part program to identify potential areas of process improvement and to assist customers in the implementation of those changes. The first part of the program incorporates assessment tasks such as site surveys and audits, condition monitoring and analysis of failed or returned parts. The second part is focused on process improvement and encompasses design and drafting, product application engineering, reverse engineering, installation and commissioning, special purpose manufacturing, component standardisation, and rotable repairs.

As O’Keefe says, it comes down to improving the reliability of the mechanical equipment and the CBC Engineering Services team assist their customers in achieving this aim.

“We assist them in their maintenance planning process. Essentially, we help our customers identify what they really need – component-wise – and when they actually need it,” he explains.

“Typically, in the water and wastewater segment there is a huge redundancy of equipment. In other words, an organisation doesn’t tend to have a singular piece of equipment that is so critical that if it fails the entire operation would stop – as that would be catastrophic when it comes to water treatment and supply,” O’Keefe expounds. “The industry is well aware of this. Where we can assist, however, is in improving the reliability of their equipment to reduce the number of maintenance events. Simply put: the fewer times they replace a part, the lesser the cost.”

Another common trait of the water and wastewater industry segment that O’Keefe’s team have experienced, is a lack of asset information among their customers. Part of this is due to the risk adverse nature of the industry – not wanting to break a process that works. This can mean there are many inefficiencies, say O’Keefe.

“Often there are pieces of equipment that are doing the same task. For example, a customer might have three pumps, two of which are made by one manufacturer and one that is made by a different manufacturer. They need to keep stock then of two different types of parts. Why not swap out the equipment so that all three pumps are the same and use the same parts?” O’Keefe asks.

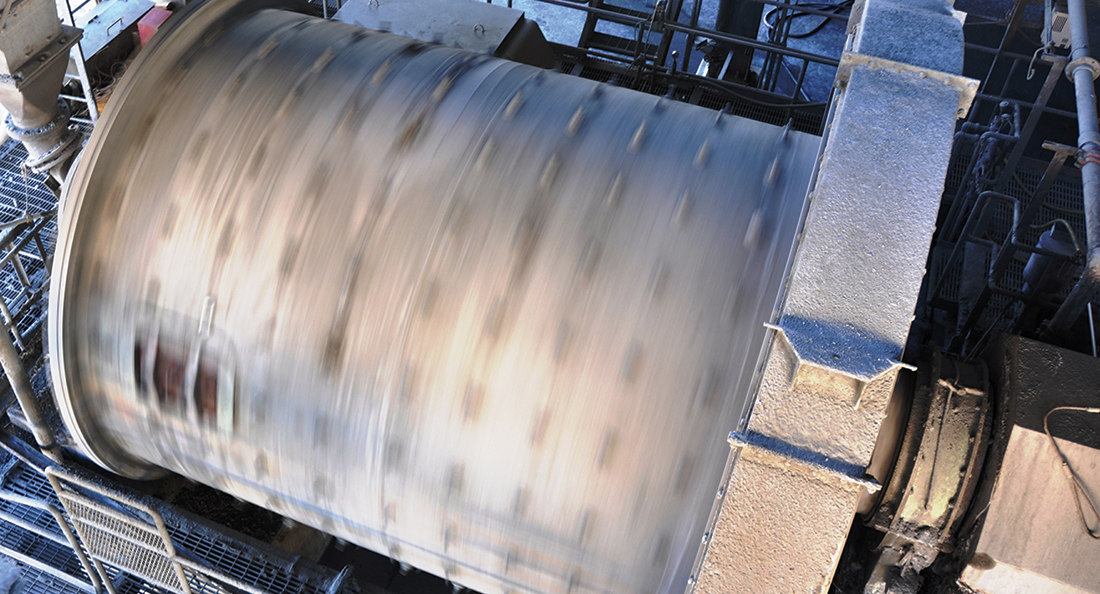

Moreover, CBC have the capabilities to draft, design and manufacture parts. This includes reverse engineering where a customer may be using a piece of machinery that is no longer manufactured. CBC can manufacture the spare parts and offer rotable repair and rebuild services as well.

“There is an ever-increasing redundancy of OEM suppliers to the market segment, and our ability to reverse engineer what was previous supplied by those OEMs puts us in a position of advantage with our customers,” says O’Keefe.

“This has been a common industry problem for as long as I can remember. We often come across equipment and parts that are no longer manufactured. There are also customers who prefer not to deal with an OEM because parts may be expensive. In either of those scenarios, we can reverse engineer it.”

Importantly, the CBC Engineering Services have a significant skills-base and can draw on their expertise and experience to assist customers.

“Because we have such a broad section of customers in the market segment, we’re able to draw learnings from customers around the country and apply those to any given site. Having such a large customer base and being able to apply these different learnings certainly sets us apart from our competitors,” says O’Keefe.

The team also take pride in finding the right solution for customers.

“We’ll take on the problem and own the solution end-to-end. From the design, drafting to the machine manufacture, to commissioning, the whole way through. By understanding the problem, we can implement a solution,” explains O’Keefe. “Personally, I love the process. It brings me great satisfaction seeing a project all the way through. It’s gratifying to achieve success but more importantly it’s in knowing that you’ve brought real value to a customer.”