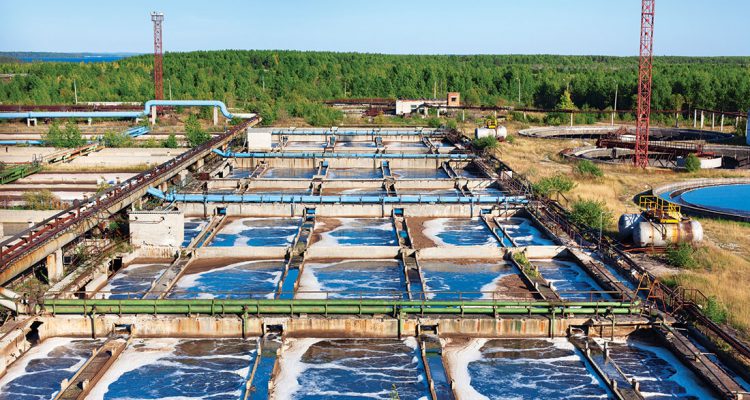

Secondary wastewater treatment removes soluble organic matter and suspended solids that remain following primary treatment. This stage involves biological processes aeration for the decomposition of solids and the use of chlorine to disinfect the liquid.

During different stages of secondary treatment, the level of oxygen in the wastewater is altered to create aerobic and anaerobic environments to produce bacteria that remove pollutants from the water.

Under anaerobic conditions, hydrogen sulphide (H2S) gas typically forms. A pollutant commonly found in wastewater, H2S can be severely corrosive to components and machinery during secondary wastewater treatment.

Standard bearings can quickly rust in such conditions. According to Tony Tormey, Industrial Bearings Product Manager at CBC, Schaeffler’s FAG Black Series radial insert ball bearing and housing units, feature a Durotect®B surface treatment to improve the bearing’s corrosion resistance to these harsh, corrosive environments.

“The advantage of the Schaeffler Black Series bearing is that the added surface protection makes it a great choice anywhere in the treatment that is subject to wash down or H2S gas, which in treatment plants can be very corrosive,” Tormey explained.

The resistance of the FAG Black series against corrosion means that it has much greater longevity, requiring less maintenance and downtime. This also makes the units suitable in wastewater plants, where downtime can be costly.

“Standard bearings usually rust within a few months, or even less, under corrosive wastewater treatment conditions – these will last much longer,” said Tormey.

Other features of the Black Series also make it a robust choice for wastewater plants. The low frictional torque of the radial insert ball bearings involves minimum heat generation and therefore maximum grease operating life. Relubrication is made easier via a seal that is firmly staked in the outer ring, which retains grease in the bearing.

Further, the vulcanised seal lip of the bearing prevents dust and water entering the bearing, while an outer flinger shield is fitted on the inner ring to protect the lip seal against damage.

“Also, these units come pre-assembled,” said Tormey. “The housing is already there and all you have to do is block it down and lock it in. Usually with other bearings, the housing and bearing are separate, and they have to be assembled together.”

The FAG Black Series housing units feature flake graphite cast iron housings with a concave bore in which the radial insert ball bearings are fitted. These units are matched to each other and are available as plummer block housing units, flanged housing units and take-up housing units.

While the FAG Black Series offers added corrosion resistance, enabling a reduction in downtime due to bearings replacements, another Schaeffler range of products is specifically designed to reduce change out times significantly: The FAG Split Spherical Roller Bearings and Housings.

Tormey said that at treatment plants, replacing bearing units in captive locations often requires operators and maintenance teams to bring in heavy machinery to move a gearbox or take a drive off, which is a significant cost in time and money.

“However, the FAG Split Spherical Roller Bearings and housings enable the unit to be installed in situ. This reduces downtime necessary for installation by around 50 per cent compared with a standard Spherical Roller Bearing and Housing” he said.

Moreover, Tormey said the Schaeffler FAG Split Spherical Roller Bearings are dimensionally equivalent to the unsplit standard types, so no additional modifications are required to the shaft or mounting locations.

“The FAG Black Series and Split Spherical Bearing and Housings ranges are stocked at CBC branches nationally, which also means that availability is not a problem” Tormey explained.

“With our expert engineering service people located at our branches around the country, we have the ability to get the customer out of trouble when they need us.”