The topic of greenhouse gas emissions came to the fore recently as world leaders attended a climate summit in April and made new pledges towards reducing greenhouse gas emissions as part of their countries’ Paris Agreement commitments.

In Australia, the electricity sector is the biggest polluter, accounting for 33% of the country’s greenhouse gas emissions.1 Any efforts to curb electricity consumption in heavy industries like mining helps the country inch closer to its target of slashing greenhouse gas emissions by 26-28% by 2030 on a 2005 baseline. This is particularly critical considering that the domestic mining sector consumes roughly 500 petajoules per year, which is 10% of the country’s total energy use.2

Michael Greelish, National Accounts Manager – Mining at CBC says adopting high-efficiency motors, with IE3 ratings and above, is one way by which mines can adhere to their emission reduction goals while also reducing their operating costs considerably.

As a key supplier of electric motors to major mines in Australia, CBC works closely with motor manufacturers, such as TECO, to work out the cost-benefits of adopting high-efficiency motors in mines, as well as in other industries. In fact, Michael says CBC’s technical teams are often engaged by their industrial customers to conduct audits to estimate a plants’ yearly electricity expenditure and potential savings with high-efficiency motors.

In one such audit recently, Michael says the CBC and TECO technical teams were able to calculate annual savings of $69,000 on electricity charges and CO2 reduction of 485.7 tonnes per year for a gold mine in Queensland simply by switching to high-efficiency TECO motors.

“The mine’s electricity costs were ridiculously high. So, we suggested conducting an audit of their site. The CBC technical team documented all of the electric motors on site, including noting each motor’s operational hours and output powers. We then used TECO’s in-house developed program to calculate not only the dollar savings, but also how much carbon credits the mine could save by using high-efficiency TECO motors,” explains Michael.

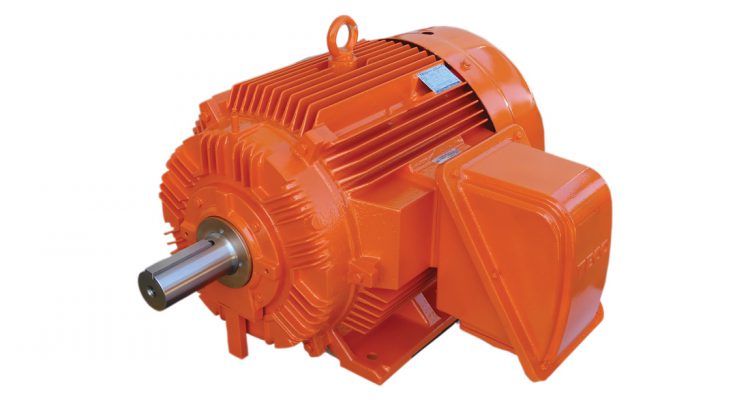

TECO’s high-efficiency motors, including the TECO MAXe3 and TECO MAXe3 Premium, are both designed specifically with the high demands of the mining industry in mind. TECO offers its motors in output range of 0.18 to 450kW, suitable for a wide range of applications.

The TECO MAXe3 high efficiency motors comply with IE3 efficiency level of IEC60034-30-1 standard and are designed to exceed the high efficiency requirements from Greenhouse and Energy Minimum Standards (GEMS) acts and regulations. TECO motor Types AEMB and AFJE meet or exceed the requirements of Australian New Zealand Standard AS/NZS1359.5-2004 Three-Phase cage induction motors within the range of 0.75 kW to less than 185 kW.

Promising a true IP66 rating, the TECO MAXe3 motors are designed to operate safely in ambient temperatures of -20°C to 60°C in mining environments. Other design features such as high-grade cast iron frame, through-flush grease-relief bearing system and a Totally Enclosed Fan Cooled (TEFC) cooling system make TECO MAXe3 ideal motors for all mining applications.

With their considerable impact on electricity consumption, Michael notes that high-efficiency motors often pay back their initial investment within only a few months.

“New electric motors often pay for their cost well within a year with savings in energy costs. That makes sense considering that around 90% of an electric motor’s total costs of ownership is related to its energy use. So once the CBC customers learn about the exact amount of savings they can achieve and also keeping in mind the additional benefits of emission reduction, switching to high-efficiency motors for their operations becomes a no-brainer,” says Michael.

REFERENCES:

1- www.climatecouncil.org.au

2- www.arena.gov.au

Key Features of TECO MAXe3 High-Efficiency Motors:

• True IP66 with porous drain plugs

• Class H insulation system

• Superior inverter- rated insulation (8500V/microsecond)

• Precision and rugged cast iron construction including fan

• 1.2 service factor at 40°C ambient

• Suitable for 60°C ambient at rated output

• TECO renowned grease relief system

• Two sets of thermistors for frames D160 and larger