Remote condition monitoring technologies have become an integral part of mining operations as companies pursue productivity improvements and aim to prevent unplanned downtime.

The technology is particularly valuable for continuous monitoring of rolling element bearings in mining equipment to alert the technicians if excessive wear is likely to cause unexpected failures. By relaying continuous data from the sensors to a remote monitoring centre, the system also enables 24-hour trend analysis to better detect signs of imminent failures. Most importantly, it eliminates the need for in-person inspections of rotating equipment, which reduces the inherent risks of such operations.

Schaeffler Australia, in collaboration with CBC, works closely with leading mining companies in Australia to set up remote condition monitoring for their assets. This is further supported by Schaeffler’s remote diagnostic services and CBC’s regular site inspections to assist the mines with preventive maintenance.

“It’s a win-win partnership,” says Rod Baker, CBC’s Mining Segment Manager for Queensland. “Schaeffler Australia is part of an extensive global network. Schaeffler have the technology and expert service to offer the best-in-class online remote condition monitoring services, while the CBC experts also have the technical knowledge and the close engagement with the major mines in Australia as key service providers to the industry. Together, we form a strong team to support customers with condition monitoring.”

Rod says a key strength of CBC and Schaeffler as a team is that once any bearing issues are identified using remote monitoring, they can also lend their expertise to investigating the root cause of the bearing failures to complement the remote monitoring service.

“CBC’s specialists are experts in bearings and are backed by Schaeffler’s global expertise as a bearing OEM. So, when the monitoring sensors detect an abnormal vibration or overheating issue with a bearing, we can go in and investigate the root cause of the problem to prevent the same problem from re-occurring,” Rod says.

“Another advantage for the mines in working with Schaeffler and CBC is that both of our companies have an extensive network across Australia. So, if a customer wishes to discuss a problem with any of our engineers, our teams are readily available to respond in detail.”

What the two companies’ symbiotic relationship has brought about for a major coal mine in Queensland is establishing a system for continuous condition monitoring of all dragline gearbox and motor drive bearings, as well as monitoring the motor and gearbox bearings in an excavator machine.

Having successfully trialed the system for three years and seeing the benefits in action, the mining company is currently considering rolling out Schaeffler’s condition monitoring solution across all draglines in their other mine sites.

Mark Ciechanowicz, Condition Monitoring and Reliability Systems Manager for Schaeffler Australia, has been involved with the project since its inception, along with CBC’s Dragline Technical Services Manager, Greg Payne.

Mark says the very first step to set up the condition monitoring system on the mine’s draglines was to determine the best locations to fit the sensors and processors on the drag, hoist, swing and propel sections of the dragline.

“The first step is always to scope out the machine and determine where to place the sensors and processors. For example, in this project we set up sensors to measure vibration, temperature and process parameters such as operational speed, direction and load on the motor drives and the gearboxes in all segments of the draglines. We also monitor the lower swing bearings in the swing gearboxes.”

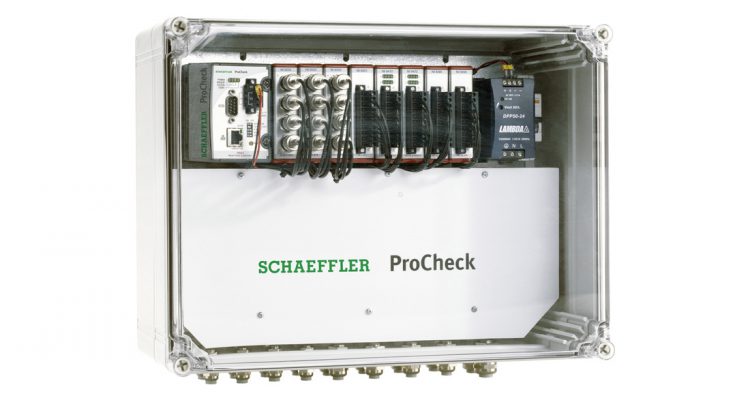

Once the required hardware is installed on-site – which would require anywhere from 7 to 10 days for each machine depending on the complexity of the equipment – Mark says the next step is establishing a wireless communication via a 3G or 4G cellular network to Schaeffler’s remote diagnostic centre. This is where the collected data is logged, analysed and the required trigger points established to be able to report the required information.

“The data from the machines gets automatically routed to the Schaeffler remote monitoring centre and our reliability engineers analyse the alarms on a daily basis so that if there’s a serious machine problem, they’ll flag that with the customer directly. They also use that data to compile a comprehensive machine diagnostic report once every month,” Mark explains.

“To analyse the data, we begin by assigning characteristic values to the frequencies of interest for each asset and its components. We can then set up alarms for each one of those frequencies of interest and it will notify us and the customer if there’s an issue, as well as showing what the issue is,” he adds.

Further, Mark says any connectivity issues that remote mines might be facing could be easily handled by Schaeffler’s technology.

“Our remote monitoring system is designed with sufficient storage capability to store data when there’s a connectivity outage and as soon as the connection is established again, the data will be transferred to the monitoring centre. In just over the last six months, we have also launched two new online systems, one using cables and the other wireless. So, our digital capabilities are growing further and further.”