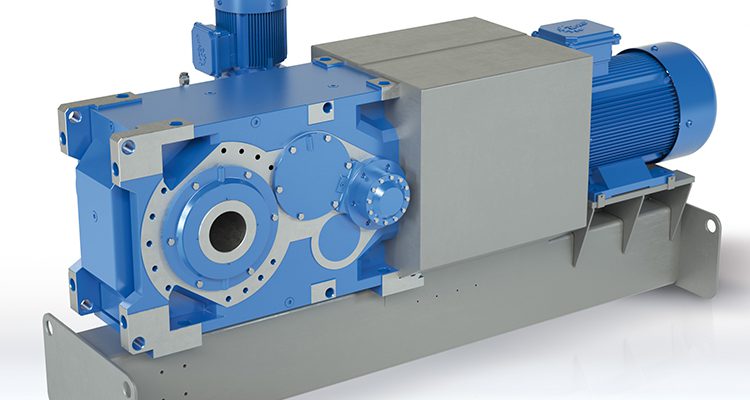

To help keep conveyors and feeders running smoothly across a variety of industries, Nord Drivesystems has implemented a line of modular industrial gear units (IGU).

Nord’s IGUs have been designed with a range of individual components that can change to match exact requirements for a specific uses.

Nord Engineering Manager, Adrian Taglieri, said the industrial gear units have been a breakthrough, allowing for transmission components to be placed together in a single housing without any forces placed on the housing joints.

“While the product has evolved over the years, it remains a prominent part of our mining product portfolio,” Taglieri said.

“By allowing customers to add their components of choice, narrowing down the delivery time and ensuring quicker installations, we add value and keep flexibility top-of-mind.”

Distributing Nord’s IGUs across Australia is Inenco, which has more than 160 branched that offer product lines for power transmission, driveshafts, drives and motors, belting, fluid power, and engineering services.

Inenco Application Engineering Manager – Power Transmission, Brad Bickford, said Inenco selected Nord as its drive partner of choice.

“We are a proud Nord distributor in Australia and have collaborated with them on many successful installations,” Bickford said.

“As a robust and flexible option, Nord’s IGUs are aimed at the mining industry. While the company has various other smaller geared motor options, the high-kilowatt IGU products prove their mettle in large mining applications.”

Inenco has previously been tasked with supplying several of Nord’s Helical-bevel drive systems for a conveyor-feeder setup at a Western Australian lithium operation.

Spearheaded by Inenco Group subsidiary, CBC, the installation involved close collaboration between distributor and manufacturer to achieve the desired outcomes.

Bickford said the right-angled, close-coupled drives was one of the company’s most ambitious Australian projects to date.

“It required six large drive systems to be implemented across four conveyors and two feeders. Nord proposed a great package that was in line with what this particular client was looking for,” he said.

“When the opportunity arose for us to supply the client, we looked at numerous options and summarised that the Nord proposal could deliver best to spec.

“What set NORD apart was the combination of a modular design, the ability to output up to 250,000 Newton metres of torque and their trademark Unicase housing design. We supplied the units in March 2018 and it then took some time for installation and commissioning, so they have been in operation for over 12 months now.”

Nord’s IGUs were fitted and driven by Teco MaxE3 premium sever duty motors, with high speed mechanical fans included to assist with cooling in a hot climate.

Bickford said the feedback so far has been positive.

Compared to rival brands, it stacks up very competitively, with quality German backing and features and benefits. It’s a quality product that ticks all the boxes.”