When it comes to the purchase and installation of valuable capital equipment, maximising its longevity and trouble-free operation should always be the end goal; this starts with ensuring a suitable foundation is in place. “The best structural grouting products are the ones you don’t have to see again after installation,” says BSC’s National Product Manager for Lubricants, Steve Keown.

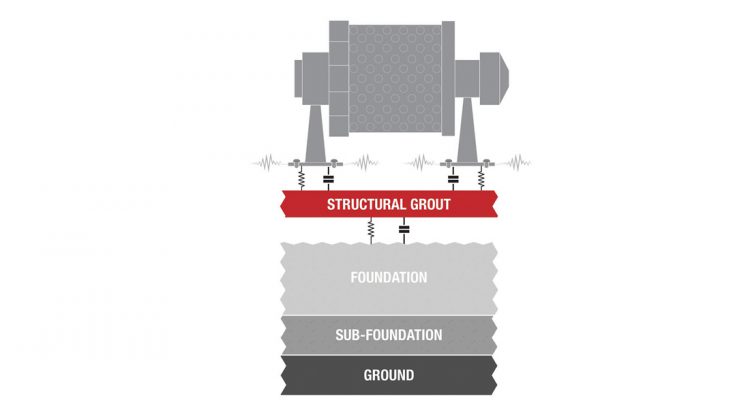

Structural epoxy grouts (or transfer mediums) and chocks are critical components in the ‘equipment system’, they are used to both distribute the heavy loads and vibration from the equipment to the underlying concrete base, as well as to facilitate proper levelling and positioning of the machine.

Keown says the durability of a grouting system is paramount, particularly when heavy impact and vibration are involved – as is often the case with heavy mineral processing equipment.

“Most mines operate 24/7. If, say, a gold mine has to shut down without prior notice, the costs could reach as high as a million dollars a day. If you add this to the cost of repairing the damaged component to get the plant up and running, it proves to be a very expensive exercise,” he says.

This is why, Keown says, BSC ensures that the products it supplies to customers are sourced from reputable brands and meet or exceed the required standards.

The Epirez® brand by ITW Polymers and Fluids (ITW P&F) is one product that stands out when it comes to grouting applications. The Epirez® brand has been manufactured in Australia since 1955 and was a pioneer in the development of epoxy-based adhesives and coatings. ITW P&F later acquired Epirez® and works with BSC as one of its major suppliers in Australia.

Keown says the two companies have developed a close-knit relationship that ensures the best products and services are available to their national customers.

“ITW P&F’s localised Account Managers work with BSC’s Regional Managers across Australia to meet all customer requirements. This includes providing the customers with the whole range of ITW P&F’s portfolio of products and brands, as well as offering our technical expertise in the area,” he explains.

Rick Williamson, ITW P&F Product Manager for Infrastructure, says the combined expertise of ITW P&F’s global technical team in conjunction with the local hands-on experience gained from assisting customers in Australia, with the help of BSC, makes the collaboration very successful.

“When it comes to installing heavy machines at a plant, even slight misalignments can be detrimental to the operation. Our expert team provides technical support through our own hands-on experience in Australia, as well as with the support from BSC to help customers choose the right product and give guidance on proper installation,” he says.

One challenge to the durability of grouting compounds, Williamson says, is temperature variations.

“Particularly in a country like Australia, there can be vast temperature differences from one place to another as well as at different times in one location. Temperature influences epoxy placement and is an important factor when it comes to selecting the right epoxy grout,” he says.

Chockfast® Red is a low-exotherm epoxy system – which means it generates less heat during the reaction process.

“Having a low-exotherm compound is particularly important when it comes to large-volume installations in high ambient temperatures – both of which are common conditions in mineral processing plants,” says Williamson.

“The mineral processing equipment, such as ball mills and crushers, are quite heavy and they often require bulky foundations. Pouring epoxy grouts in deep cross sections generates excessive heat that can cause the installation to fail.

The Epirez® Chockfast® Red is suitable for large volume installations with thicknesses as high as 460 millimetres. Chockfast® Red has extremely high compressive strength and is ideal for installing critically aligned machinery within very close tolerances.

“Even when the ambient temperature is very high, like within a mineral processing plant or inside a mine, Chockfast® Red can control the exotherm to keep the temperature in check. This prevents the risk of cracking and failure,” says Williamson.

The Epirez® Chockfast Red®, along with other products from ITW P&F is available through BSC’s distribution network.

Keown says when it comes to choosing grouting and wear-related compounds, BSC is very sensitive on supplying only products that have obtained all of the relevant global standards of quality.

“We have found ITW P&F to be on the right side of it. Through working with ITW P&F, we are confident that the customers are getting products that will endure their working conditions, without causing unnecessary repair burdens,” he concludes.