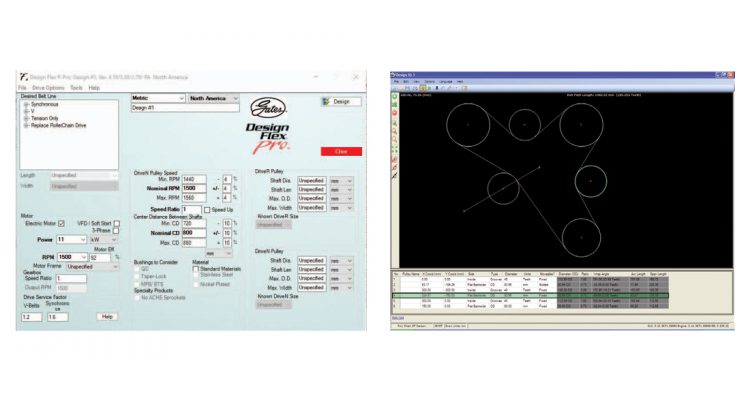

A quarry or mining plant potentially has hundreds of different belt drives. How can a site or reliability manager ensure belts are achieving their life expectancy and that drives are working at optimal efficiency? According to Steve Hittmann, the Gates® Design Flex™ Pro™ free software tool is designed exactly for this purpose, providing real cost savings and benefits to customers.

“We supply this software as a free issue to our customers – for example, if they’re having an issue with a belt drive, they can enter the particulars of that belt drive and the software will analyse the efficiency of the drive for their application,” explains Steve, who is the National Product Manager for Mechanical Drive Systems with CBC Australia. “It is an incredibly useful tool that can be used to design new belt drives, confirm the suitability of existing drives and obtain correct maintenance procedures and tension details.”

Steve reflects on one particular quarry customer who was not achieving the estimated manufacturer’s life expectancy out of their belt products.

“In this case, the customer contacted us to get a quick answer and resolution. We used this Design Flex™ Pro™ tool to confirm the existing drive information and suitability to the applications. By keying in the relative details, we had visibility on all the previous drives used, and were able to reduce the set of 12 belt drives to the one type,” Steve expands. “What did this mean for the customer? First of all, we switched to a Gates® product, which is a premium product that provides better performance and longevity. Secondly, by consolidating the belt drives the customer realised significant cost savings.”

Moreover, Steve says CBC often uses the Design Flex™ Pro™ tool when performing site surveys.

“Whilst the software serves as a belt drive selection tool, it is also used to determine proper belt installation tension, calculate belt pull and determine the rated belt capacity,” Steve furthers. “It can also estimate the energy savings of a synchronous belt drive compared to a V-belt drive, estimate the cost savings of replacing roller chain with a Poly Chain® GT™ Carbon™ belt drive and can compare noise levels of different Gates® synchronous belt drives.”

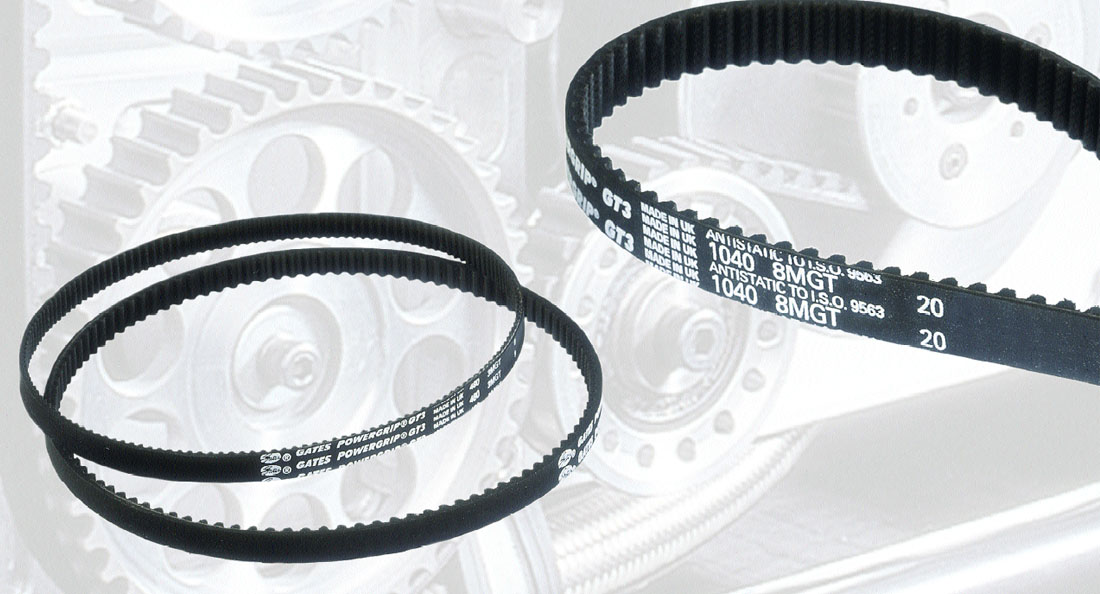

In regards to the quarry customer, Steve points out that together with using the tool to determine the suitability of the drive system, the Gates® belt solution was a good fit because of the belt’s premium design and features.

“Both Gates® and CBC have similar philosophies – we believe in providing quality products and solutions that give our customers good value for money. Gates® exclusively make quality products,” Steve enthuses. “Whilst customers may pay a bit more initially, these are top end, premium products that will require less maintenance and replacement costs. Other noteworthy features that made Gates® a good choice for the quarry customer include the close manufacturing tolerances and cross section profile with its curved side walls.”

Significantly, Steve says Gates® outperform competitors on the life expectancy front.

“Gates® aims to provide 25,000 hours of life, and deliver on that. The Gates® standard is three years continuous running and usage,” Steve states. “Whereas competitors tend to provide between 6,000-12,000 hours of life.”

Customers also stand to benefit from both the industry experience and expertise of the CBC team, which affords them access to Gates’ technical support and advice as well.

“We are ‘premium partners’ in every sense of that title – we partner to problem solve and bring long-lasting solutions to our customers, and we provide premium services and products,” says Steve. “We are often seen in the field together, and customers get to leverage our collective skillset, expertise and experience.”

To summarise, Steve says the Gates® Design Flex™ Pro™ is yet another valuable resource to add to the toolbelt.

“We apply this to applications by proposing new drives, confirming the suitability of existing drives and by measuring and ensuring they are working efficiently,” he concludes. “Ultimately this means less maintenance for the customer, longer life of their belt drives, improved reliability and cost savings.”

Gates Design IQ™

Easily design multi-point and complex serpentine belt drives for your specific application. Gates Design IQ™ is a downloadable engineering software that lets you design for stock and nonstock lengths and pulley sizes, with customised sprockets and conditions. Simply identify a specific Gates product, enter your drive specifications, and Gates Design IQ™ will calculate belt tension, shaft load, and belt length for you.

You can use Design IQ to:

- Calculate belt tension, belt length, shaft load, and more

- Recommend installation tension

- Offer drive geometry output

- Point out principal contributing factors to flex-fatigue

- Calculate belt widths or number of strands