Silicosis has been flagged as a problem in the Australian mining industry since the beginning of the 20th century1. Yet the dust disease is still prevalent today. Over 600,000 Australian workers are exposed to silica dust each year and an estimated 230 develop lung cancer as a result2,3.

“In mines and quarry sites, there are a number of operational processes that produce dust – silica is a commonly occurring mineral found in most rock, so any activity that involves the crushing of rock can result in exposure,” explains Michael Rowe, Product Manager for Safety with CBC Australia. “While it’s not a new issue – in fact the Government has highlighted silica exposure as a key industry issue since the 1920s – the fact is this disease kills, and as it’s still the cause of so many deaths, it remains a serious problem.”

Which is why Michael says workplace controls are critical.

“Silicosis is preventable through controls that either stop or reduce the amount of silica dust,” he stresses. “As there is no cure for silicosis, prevention is the only option.”

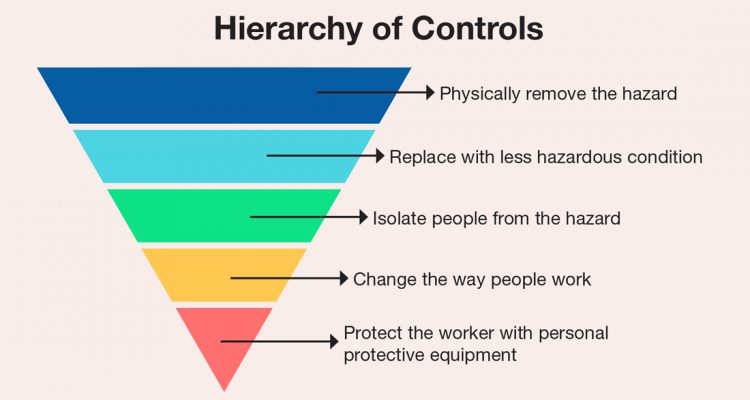

Mines and quarries are of course subject to Work, Health and Safety (WHS) regulations that require them to evaluate risks and implement a Hierarchy of Controls4. Nonetheless, Michael points out that it is still up to individuals to follow the rules. This is particularly important when it comes to wearing respiratory protection equipment (RPE), which is often referred to as the ‘last line of defence’.

“Workers in these industries should heed their site safety rules if they want to avoid having underlying problems in their future years,” he explains. “Masks are not always fun – as everyone nationally has now experienced – and when you’re onsite and working hard, wearing a mask can be particularly challenging. This is why having the right respirator and fitment to suit your working environment is vitally important. It’s so you get to go home healthy at the end of the day.”

Furthermore, Michael says it is fundamental employers “make sure the RPE is fit for purpose, not fit for price.”

When it comes to advising customers about RPE, however, he defers to the knowledge and expertise of CBC Australia’s premium partner, 3M.

“We facilitate consultations between the 3M team and our customers when it comes to specific respiratory enquiries, as they are the experts in this field,” Michael expands. “Being able to leverage this kind of technical expertise from our partners – along with the breadth and range of products we supply – is one of the key benefits we offer to customers.”

Mark Reggers is one such expert that CBC Australia would direct any enquiries that require specialist attention. As both an Occupational Hygienist and Application Engineering Specialist for 3M in the Personal Safety Division, Mark provides technical and user support around the 3M respiratory protection range, including educational and training workshops on the prevention of silicosis. He draws on over 19 years’ experience in the safety and PPE industry.

“Silicosis is an example of an occupational lung disease where the immediate effects of exposure are often not realised, but the cumulative exposure can be fatal,” he cautions. “Unfortunately, by the time those long-term effects are visible, it’s already too late.”

Mark attributes part of the recent media focus on silicosis to changes in the Workplace Exposure Standard (WES).

“Safe Work Australia recently halved the exposure standard for Respirable Crystalline Silica (RCS) which is one of the reasons it’s been brought into focus,” he explains. “But the WES alone doesn’t make the workplace safer. It’s the controls and practices in the workplace that make it safer.”

Importantly, Mark notes that if PPE – which is the last tier of control in the Hierarchy of Controls recommended by WHS – is required, then it is no less important than any other control.

“In fact, it may be even more important because it is that last line of defence,” Mark contends. “In specific mine and quarry applications, they’re still going to be relying on PPE to protect workers from deadly dust exposure.”

The biggest challenge with PPE and particularly RPE is that it relies on worker behaviour in order to be effective 100% of the time.

“Which is why it is at the lowest level in the hierarchy. Other controls in place don’t require the worker to actively participate or behave in a certain way,” Mark says. “Think about what the ‘P’ stands for in PPE. It’s personal. With respirators in particular, it’s got to be right for the individual person, it’s got to fit them correctly.”

Which is why when PPE is required, workplaces need to develop a Respiratory Protection Programme (RPP), as per the AS/NZS 1715 Standard. However, Mark notes that this in itself is another challenge, as “often workplaces aren’t aware of what a Respiratory Protection Programme actually entails”.

“It is not as simple as picking out a respirator from a catalogue, it requires a systematic approach to provide the level of confidence and likelihood that workers are going to be protected,” Mark states. “There are three points that must be addressed with RPE. The first is the filter, the second is the adoption – as it needs to be worn 100% of the time when protection is required, and the third is it has to fit the wearer to create an adequate seal.”

Additionally, Mark says there are a plethora of other factors that fall within those three main categories that need to be considered.

“Employers need to ask, is the respirator adequate and is the respirator suitable? Because both need to be addressed,” Mark says. “Selecting respiratory equipment goes well beyond the filter. Facial structure, facial hair, the length in which a task is performed, environmental conditions, physiological impacts and communication requirements should all factor into a selection process.”

In regard to silica, Mark says any rated particulate filter – P1, P2 or P3 – would be adequate, but the question to ask is will the respirator that the filter attaches to be suitable? Are there other co-exposures that require a certain level of filtration, for example, diesel particulate matter (DPM) which requires a P2 as a minimum? The aforementioned factors come into play, as does cost.

Significantly, products such as the 3M three-panel flat fold mask, which is a popular choice, need to be fit tested just like any tight-fitting respirator.

“The fit test is critically important with these respirators. Every person has a different facial shape,” Mark reiterates. “They’re also not ‘set and forget’, which is where training and education around the fit testing is equally important.”

Moreover, all tight-fitting respirators require a clean-shaven face.

“Facial hair is a huge issue. All the standards for tight fitting face piece respirators require that individuals are clean shaven – because studies show that any level of facial hair will significantly reduce the expected level of protection,” Mark explains. “This means there has to be workplace supervision as well to ensure employees are clean shaven. Facial hair is a moving target, as it changes every day.”

This is why powered air purifying respirators (PAPR) with loose fitting headtops, such as the 3M Versaflo™ range may instead be the better choice.

“While the capital outlay will be more, they can be worn with certain styles of facial hair, do not need to be fit-tested and are much more comfortable due to the reduced breathing resistance,” says Mark. “Besides offering respiratory protection, these can include other protections, including a hard hat, a communication device, and users can attach earmuffs.”

Another respirator that 3M recently brought to market is the half face reusable HF800, which has the world’s first quad flow cartridge system to improve breathing resistance. It also includes a push button seal check and speaking diaphragm to improve worker communication on the job. Poor communication can introduce other hazards and risks into the situation.

However, when it comes to the selection criteria for protection against silica exposure, Mark restates the importance of a Respiratory Protection Programme.

“This will start with the question of how much silica is there? Understanding the level of exposure is essential to quantifying the risk and the appropriation of PPE,” he states. “Then you need to factor in the suitability of the respirator and be methodical in that process.”

Mark also advises readers to take advantage of the bevy of free resources available, including specific online resources for the mining and quarrying sectors.

“There’s a myriad of free and valuable resources available – including our 3M podcasts and online hub for respiratory protection,” he concludes. “We know silica is a hazard. We know the controls. There is a moral and ethical obligation to ensure worker safety from this preventable disease.”

References:

The struggle against silicosis in the Australian mining industry: The role of Commonwealth Government, 1920-1950, https://www.jstor.org/stable/27509198

Is your workplace safe from silica dust? https://www.awu.net.au/national/news/2019/12/7849/is-your-workplace-safe-from-silica-dust-2/

Cancer Council, https://www.cancer.org.au/cancer-information/causes-and-prevention/workplace-cancer/silica-dust

Safe Work Australia, https://www.safeworkaustralia.gov.au/silica