Experts in metallurgy will be familiar with what is known as ‘froth flotation,’ in which a cylindrical flotation cell will typically hold the materials, while a low-pressure blower will parse the particles into hydrophobic (water-repellent) and hydrophilic (water-soluble) materials using air bubbles that are carried across the surface and removed.1

When CBC Regional Mining Manager, Sam Wilkinson, received a query from a copper mining customer in Northern Queensland about a bearing failure analysis on one of their flotation blowers, he moved quickly to draw up a proposal that included an NTN bearings solution.

“Our engineering team headed to the site first to do a load case. We check the load capacity of the existing bearing, the speed and the overall suitability of the bearings and determined a better solution,” says Sam.

“The flotation blower fan is absolutely critical to creating the flotation bubbles in a copper concentrator cell,” explains Sam. “The fans move at very high speeds, and in this case the spherical roller bearings the customer was using on the fan were slipping due to poor axial and radial loading, causing bearing failure every 8-12 months.”

“From this, we proposed a new fan barrel assembly to the customer. We suggested using a pair of NTN Angular Ball Bearings (7226) for the shaft to reduce skid, and a single NTN Deep-Groove Ball Bearing (6226) for a smoother barrel assembly.”

According to Sam, there were a lot of moving parts in the new design, requiring cooperation across the business – with the key components being the custom bearings solutions supplied by NTN.

These types of engineering projects must be approved by the Registered Professional Engineer Queensland (RPEQ) standard before going to manufacturing, Sam explains.

“Once the RPEQ process is approved and the customer accepts the design, we then manufacture at the CBC Design Hub in Sydney. Experts Josh Price, Engineering Hub Manager and Marcello Falcao, Senior Application Engineer were heavily involved in the production process for this project.”

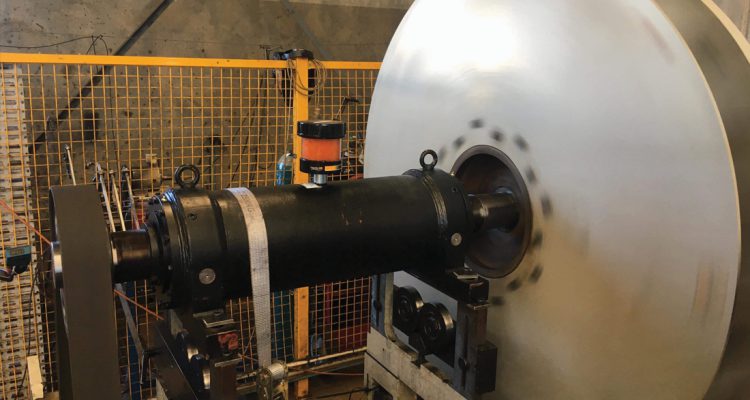

Because it was such a change from the original fitted bearing, the customer requested that the team at CBC perform some acceptance testing off site. “We shipped it from Sydney to Townsville, where we put it on an industrial balancing machine,” explains Sam. “We monitored the temperature and vibration, and after passing specs, we shipped it out to the customer site.”

The seamless collaboration between the CBC Queensland engineering team, the Sydney manufacturing facility, the inhouse balancing service from a group company (Hardy Spicer) and technicians on the ground allowed for a complete solution for the customer. Furthermore, the joint venture between NTN-CBC also allowed for a quick turn around on supply.

Fabio Rebecchi, National Product Manager for NTN-CBC describes why the solution was such a good fit.

“The angular ball and deep-groove bearings solutions are ideal for a fan application rather than spherical rollers bearings. In flotation fans, spherical roller bearings tend to skid at very high speeds because there isn’t enough load through the bearing,” explains Fabio.

“These bearings are ground to face which allows for universal pairing. In this instance, the team at CBC have used a back-to-back arrangement which allows an axial load from one direction where the fan would be. Then on the other side, there is a deep-groove ball bearing which provides excellent load to medium radial load.”

To summarise, Fabio says: “The best things that we do in our business happen because we have the right structure, the right stock, the right support, and the right people facing the customer, and when it happens, it happens seamlessly as an organisation.”

References: